Improve the production efficiency of peanut oil press

With the increasing production of oil crops, the demand for peanut oil press is rapidly increasing. The peanut oil press is easy to operate and has a small investment. It has been widely used in rural areas. Use the peanut oil press correctly, understand the application of its key technologies, and find out in time. It is very important to solve the fault and improve the production efficiency of the equipment.

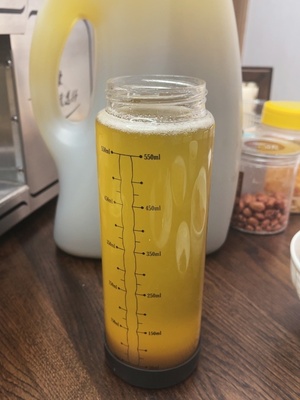

1. Preform moisture content. The preform has too little water content to form a cake and cannot squeeze out oil. The preform has too much water content, and the raw materials are in plastic packaging without clogging. When the pressing pressure drops, no oil can be squeezed out. Normally, raw materials with higher oil content should have less moisture content under certain temperature conditions due to the high squeezing pressure.

2. Squeezing temperature, the squeezing temperature is too low, the oil viscosity is high, it is difficult to flow and polymerize, the temperature is too high, the power consumption of the equipment is large, and the parts are easy to wear. Generally, the temperature of cold pressing is controlled at 60-90 degrees, and the temperature of hot pressing is 100-130 degrees.

3. Rotation speed of snail squeezing. If the snail squeezing speed is high, the squeezing time is short and the amount of raw material processed is large, but the oil yield is low. On the contrary, if the speed is low, the squeezing time is long, the oil yield is high, but the productivity is low. The hot pressing speed is 36-38r/min. The cold pressing speed is 85-120r/min.

4. Squeeze the stick out of the oil gap. If the oil outlet gap is too narrow, the oil flow will be poor and the oil output rate and productivity will be reduced. If the gap is too wide, the press chamber pressure will be low, and the slag content in the oil will be high, which will affect the quality of the oil. For raw materials with high oil content, such as peanuts and soybeans, the oil gap should be larger. Generally, the gap should be 0.07-1.00mm

5. Number and time of squeezing. The number of squeezing passes and time should be determined according to the specific conditions. The number of squeezing passes is related to the squeezing process. It can be squeezed out once cooked, and it needs to be squeezed twice. If the pressing time is too long, the production efficiency will be reduced.